About Control Loop:

Modern production systems use automatic control systems where control is carried out with minimal or without human intervention. The ‘Control loops’ used in a process industry in terms of a combination of two or more instruments or control functions arranged so that signals pass from one to another for the purpose of measurement and/or control of a process variable. The goal of process control instrumentation is to measure, monitor, and or control a process.Following three tasks is associated with a control loop.

- Measurement

- Comparison

- Adjustment

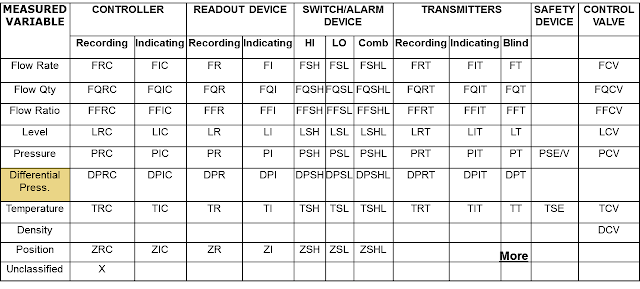

- Instrument and controller symbol and identification letter.

- Different type of function symbols and their uses.

- Symbol of different type of line and device associated with control loop.

- Instrument numbering.

To read out a control loop fro a P&ID first we have to identify the following things:

- Variable/variables are to be controlled by the control loop.

- Variables need to measure for functioning the control scheme.

- Type of instrument used for measuring variable.

- Type of controller, device and function used for controlling purpose.

- Type of signal and connection used for interlinking and transmission purpose.

EXAMPLE:

Here the control loop is working in following steps:

In the above example the tank is filling with the pipe line above the tank and emptying through the bottom pipe line. The level of the liquid in the tank need to control for process purpose. So the control loop is designed here just to control the tank level. The level or height of the liquid is the process variable here and the level transmitter (LT) is used to measure the process variable continuously.A level controller (LC) is used as controller and a level control valve (LV) is used to control the flow inside the bottom pipe line.

Here the control loop is working in following steps:

- First the level transmitter (LT) is measuring the level.

- The measuring value is transmitted to level controller (LC) through electrical signal.

- The controller decide what to do depending on set or desired value.

- Then the controller send required command to the level control valve (LV) through a pneumatic signal.

- Finally the control valve increase or decrease the flow as per controller signal.